The production process of paper drawing

2025-02-24

The Production Process of Paper Drawing

The art of paper drawing has been cherished for centuries, serving as a medium for artists to express their creativity and ideas. However, behind every exquisite piece of paper lies a meticulous production process that transforms raw materials into a versatile drawing surface. This article delves into the various stages involved in the production of paper specifically designed for drawing, highlighting the materials used, the manufacturing techniques, and the importance of quality control.

The first step in the production of drawing paper begins with the selection of raw materials. The primary ingredient in paper production is cellulose, which is derived from wood pulp. The type of wood used can vary, with common sources including pine, spruce, and birch. Each type of wood contributes different characteristics to the final product, affecting the texture, absorbency, and overall feel of the paper. In addition to wood, recycled paper fibers are increasingly being utilized to promote sustainability within the industry. This shift not only reduces waste but also lowers the demand for virgin materials, making the production process more environmentally friendly.

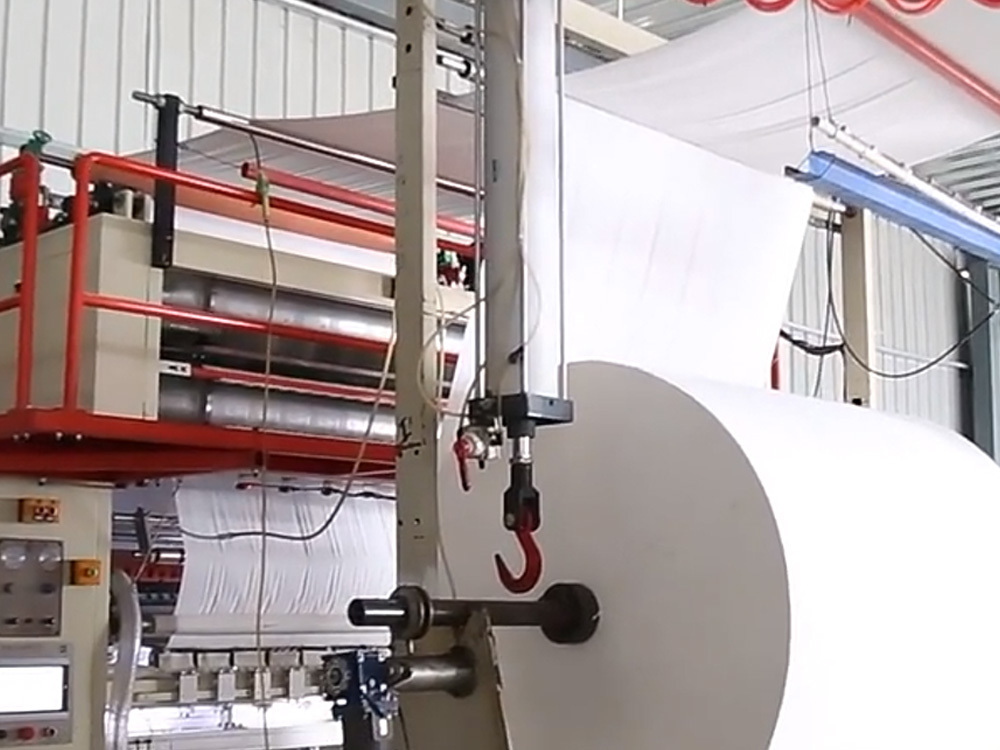

Once the raw materials are sourced, the next phase involves pulping. This process breaks down the wood chips into a slurry of cellulose fibers. There are two primary methods for pulping: mechanical and chemical. Mechanical pulping involves grinding the wood chips, while chemical pulping uses chemicals to dissolve the lignin that binds the cellulose fibers together. The choice of pulping method significantly influences the quality of the paper. For drawing paper, chemical pulping is often preferred as it produces a smoother surface that allows for better ink and pencil application.

After pulping, the slurry is washed and refined to remove any impurities. The refining process is crucial, as it enhances the bonding ability of the fibers, resulting in a stronger and more durable paper. During this stage, additives such as fillers and sizing agents may be introduced. Fillers, such as calcium carbonate or kaolin clay, improve the paper's opacity and brightness, while sizing agents, such as starch or rosin, enhance the paper's resistance to ink bleed and water. These additives are particularly important for drawing paper, as they affect how well various mediums adhere to the surface.

Related News

LATEST

INFORMATION

Get the latest product information of the company

CONTACT

Kang mei industrial zone, Quanzhou City, Fujian Province , China

Get a Quote

Fill in your phone and E-mail information to solve your problem as soon as possible.

Copyright © Quanzhou Aiyuan Hygiene Products Co., Ltd.